In the ever-evolving food industry, packaging plays a pivotal role not just in preserving the quality of products but also in enhancing brand identity and ensuring customer satisfaction. Food packaging box specifications, often overlooked, are the unsung heroes that determine the success of a product on the shelf and beyond. From material selection to structural design, every detail matters in creating packaging that is both functional and appealing.

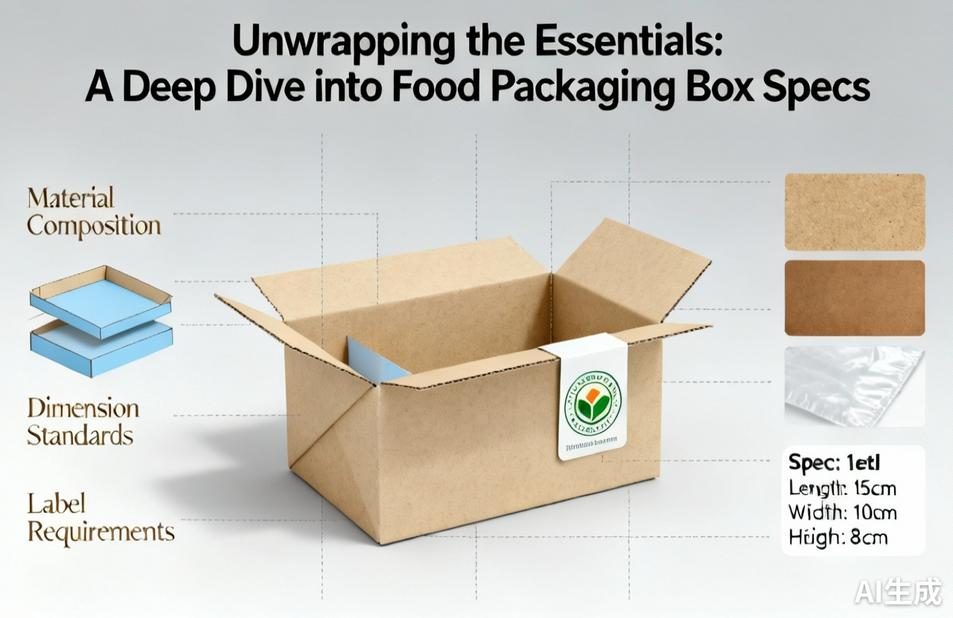

When it comes to food packaging, the material is the first and most critical consideration. Options range from cardboard and corrugated fiberboard to biodegradable plastics and compostable materials. Each has its unique advantages: cardboard is sturdy and recyclable, while biodegradable options appeal to eco-conscious consumers. The thickness, often measured in microns or grams per square meter (GSM), directly impacts durability and protection. For instance, a higher GSM cardboard box can better withstand moisture and handling during transit, ensuring that delicate items like pastries or fresh produce arrive intact.

Size and dimensions are another cornerstone of food packaging specs. Custom-sized boxes not only reduce material waste but also provide a snug fit that minimizes movement and potential damage. Internal partitions or inserts can be incorporated for multi-item packages, such as assortments of chocolates or baked goods, keeping each piece secure and presentation-ready. Additionally, considering stackability is crucial for storage and logistics—well-designed boxes should be easy to pile without compromising structural integrity.

Functional features like closures, handles, and windows add both practicality and aesthetic value. Zip locks or tamper-evident seals ensure freshness and safety, while die-cut windows allow customers to view the product without opening the package—a key selling point for items like gourmet cookies or artisan bread. Handles make carrying convenient, enhancing the unboxing experience for takeaway or gift packages. These elements, though small, significantly influence consumer perception and usability.

Printing and branding on food packaging boxes cannot be ignored. High-quality printing techniques, such as offset or digital printing, bring vibrant colors and intricate designs to life, helping brands stand out. Food-safe inks are mandatory to avoid contamination, and finishes like matte or gloss lamination can protect the print while adding a tactile element. Including essential information—ingredients, nutritional facts, branding logos, and recycling instructions—is both a regulatory requirement and a trust-building measure with consumers.

Sustainability is no longer a trend but a necessity in food packaging. Specifications now often include eco-friendly certifications, such as FSC (Forest Stewardship Council) for paper-based materials or compostability labels. Lightweighting—reducing material use without sacrificing strength—is gaining traction to lower carbon footprints and shipping costs. Brands that prioritize green specs not only contribute to environmental conservation but also resonate deeply with modern, conscious buyers.

In conclusion, food packaging box specs are a multifaceted aspect of product development that blends science, art, and strategy. By carefully selecting materials, optimizing dimensions, incorporating functional features, and embracing sustainability, brands can create packaging that protects, promotes, and perseveres. In a competitive market, these details make all the difference between a product that merely exists and one that excels.

Leave a Message