In the world of logistics and product preservation, moisture is public enemy number one. From electronics to pharmaceuticals, from luxury goods to food items, uncontrolled humidity can transform premium products into worthless inventory within days. This is where the humble moisture-proof packaging box emerges as an unsung hero in the supply chain. These specialized containers do more than just hold products—they create micro-environments that shield valuable goods from one of nature’s most persistent threats.

Modern moisture-proof packaging represents a fascinating intersection of material science and practical engineering. Unlike standard cardboard boxes, these containers incorporate multiple protective layers including aluminum foil, polyethylene coatings, and specialized desiccants that actively absorb ambient moisture. The most advanced boxes maintain internal humidity levels below 10% even when external conditions reach 90% humidity—a critical threshold for preventing mold growth, corrosion, and product degradation.

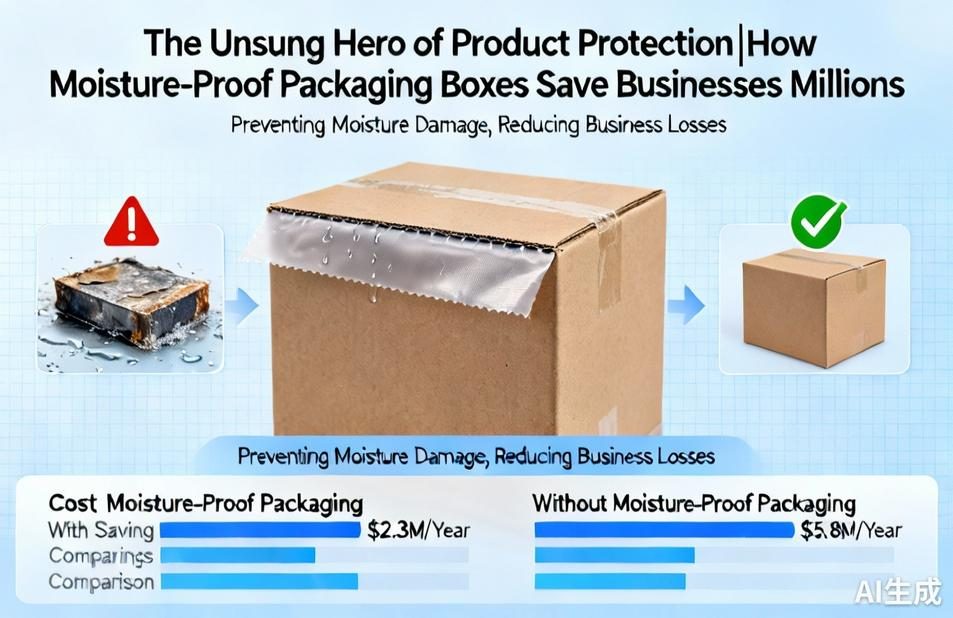

The economic impact of moisture damage is staggering. Industry reports indicate that businesses lose approximately $50 billion annually to humidity-related product spoilage. For electronics manufacturers, a single shipment of moisture-damaged circuit boards can mean six-figure losses. Pharmaceutical companies face even greater risks when humidity compromises medication efficacy. Moisture-proof packaging boxes offer a surprisingly cost-effective solution, typically adding only 5-15% to packaging costs while reducing spoilage rates by up to 95%.

What makes these packaging solutions particularly remarkable is their adaptability across industries. Food companies use moisture-proof boxes with oxygen barriers to extend shelf life without preservatives. The art world relies on climate-controlled packaging to transport valuable paintings and artifacts. Even the cannabis industry has embraced advanced moisture-proof packaging to maintain product consistency and compliance with strict humidity regulations.

The technology behind moisture-proof packaging continues to evolve at an impressive pace. Smart packaging now incorporates humidity indicator cards that change color when moisture levels become critical. Some advanced systems even include wireless sensors that alert supply chain managers to environmental breaches in real-time. These innovations transform packaging from passive protection to active monitoring systems that provide valuable data throughout the product journey.

Environmental considerations have also driven significant improvements in moisture-proof packaging design. Early versions relied heavily on plastics, but contemporary solutions increasingly use biodegradable moisture barriers and recycled materials. Many manufacturers now offer take-back programs where used moisture-proof boxes can be returned, refurbished, and reused—creating circular economies that benefit both businesses and the environment.

Implementing effective moisture protection requires more than just selecting the right box. Successful moisture management involves understanding product-specific requirements, supply chain conditions, and seasonal variations. Companies working with moisture-sensitive products should conduct thorough humidity mapping of their distribution channels and consult with packaging specialists to develop customized solutions. The initial investment in professional assessment typically pays for itself within the first year through reduced spoilage rates.

As global supply chains become longer and more complex, and as climate change introduces greater weather variability, the importance of reliable moisture protection will only increase. Forward-thinking companies are already treating packaging not as an expense but as a strategic investment in product integrity. The moisture-proof packaging box, once an afterthought, has rightfully taken its place as a critical component in modern business strategy—protecting products, preserving value, and building consumer trust one shipment at a time.

Leave a Message