In the bustling world of global trade and e-commerce, there exists a silent workhorse that has fundamentally transformed how goods move across continents – the humble corrugated box. While often overlooked, this unassuming packaging solution has become the backbone of modern logistics, enabling everything from next-day deliveries to international shipments with remarkable efficiency and reliability.

The genius of corrugated packaging lies in its ingenious three-layer design. The fluted medium sandwiched between two liners creates a structure that combines lightweight flexibility with surprising strength. This engineering marvel provides exceptional cushioning protection while remaining cost-effective to produce and transport. The air circulating within the flutes acts as natural insulation, protecting contents from temperature fluctuations and physical impacts during transit.

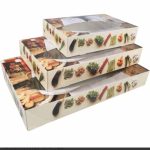

Modern logistics operations have been completely reshaped by corrugated boxes’ versatility. Standardized sizes allow for optimal space utilization in shipping containers and warehouse shelves, while custom designs accommodate products of every shape and size. The development of weather-resistant coatings and reinforced edges has further expanded their capabilities, making them suitable for perishable goods, fragile items, and even heavy industrial components.

Sustainability has become another compelling advantage of corrugated packaging in logistics. With approximately 90% of corrugated boxes being recycled, they represent one of the most environmentally responsible packaging solutions available. The industry’s commitment to using renewable materials and improving recycling infrastructure continues to strengthen its green credentials, aligning perfectly with modern consumers’ environmental concerns.

The integration of technology has elevated corrugated boxes from simple containers to smart logistics solutions. Printed barcodes, QR codes, and RFID tags transform each box into a trackable unit within the supply chain. Smart packaging innovations now include moisture indicators, shock sensors, and even temperature monitors printed directly onto corrugated surfaces, providing real-time data about shipment conditions throughout the logistics journey.

E-commerce’s explosive growth has further cemented the corrugated box’s indispensable role in logistics. The rise of omnichannel retail demands packaging that can transition seamlessly from warehouse shelves to customer doorsteps while maintaining product integrity. Corrugated boxes offer the perfect solution – easy to assemble, simple to open, and designed for efficient returns processing, addressing the complete lifecycle of modern retail logistics.

Looking ahead, the future of corrugated boxes in logistics appears brighter than ever. Advances in material science are producing stronger, lighter boards while reducing environmental impact. Digital printing technologies enable high-quality, customized graphics without compromising recyclability. The development of automated packaging systems that select ideal box sizes for each order continues to optimize supply chain efficiency while reducing material waste.

From protecting precious cargo across oceans to ensuring your online orders arrive in perfect condition, corrugated boxes have earned their place as the unsung heroes of global commerce. Their continued evolution promises even greater efficiency, sustainability, and innovation in the logistics landscape. The next time you receive a package, take a moment to appreciate the sophisticated engineering and strategic planning embodied in that simple brown box – the cornerstone of our connected world.

Leave a Message