In an age where e-commerce dominates and global supply chains stretch across continents, there exists a silent powerhouse working tirelessly behind the scenes – the corrugated box factory. These manufacturing marvels produce what many consider the backbone of modern logistics: the humble yet incredibly sophisticated corrugated box. From protecting precious electronics to delivering fresh produce, these factories operate with precision engineering and sustainable practices that would surprise even the most seasoned industry observers.

Step inside any modern corrugated box facility, and you’ll witness a symphony of automated machinery and skilled craftsmanship. The process begins with massive rolls of paper – some as wide as a car is long – feeding into colossal corrugators that transform flat sheets into the characteristic fluted medium. This fluted structure, sandwiched between linerboards, creates what engineers call the ‘arch effect,’ providing exceptional strength and cushioning while using minimal material. The mathematics behind these corrugations isn’t random; it’s precisely calculated to provide maximum protection with optimal material usage.

Today’s corrugated box factories are technological wonderlands. Advanced computer systems monitor every aspect of production, from moisture content in paper rolls to the precise temperature needed for optimal adhesive bonding. High-speed flexographic printers can produce vibrant, detailed graphics at speeds exceeding 10,000 boxes per hour, while robotic arms stack and palletize finished products with superhuman precision. The integration of IoT sensors and AI-powered quality control systems ensures that every box meets exact specifications before it ever leaves the factory floor.

What truly sets modern corrugated box manufacturers apart is their commitment to sustainability. The industry has embraced circular economy principles with remarkable success. Over 90% of corrugated packaging gets recycled, making it one of the most recycled materials on earth. Factories increasingly use renewable energy sources and have reduced water consumption by up to 70% compared to decades past. Many facilities now operate as ‘paper mills in reverse,’ where used boxes return to become new ones in a continuous, environmentally-conscious loop.

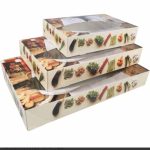

The innovation doesn’t stop at basic rectangular containers. Corrugated box factories now produce engineered solutions for virtually every industry imaginable. Temperature-controlled boxes with integrated phase-change materials protect pharmaceuticals during transit. Water-resistant coatings enable seafood shipments to maintain perfect conditions. Specially designed partitions create custom compartments for fragile electronics, while heavy-duty triple-wall constructions can support weights exceeding 1,000 pounds. The versatility of corrugated material continues to surprise even the most demanding clients.

Behind every successful corrugated box factory lies a team of dedicated professionals – from materials scientists developing stronger paper composites to logistics experts optimizing supply chain efficiency. These factories employ thousands of skilled workers who understand the delicate balance between structural integrity, cost efficiency, and environmental responsibility. Their expertise transforms simple paper into sophisticated protective systems that withstand the rigors of global shipping while minimizing ecological impact.

As e-commerce continues to grow and consumer expectations evolve, corrugated box factories are rising to meet new challenges. Smart packaging with integrated tracking technology, compostable coatings, and even boxes that transform into retail displays are already in production. The factories of tomorrow will likely incorporate even more advanced materials and digital integration, ensuring that this centuries-old invention continues to serve modern commerce in increasingly innovative ways.

The next time you receive a package or stock store shelves, take a moment to appreciate the engineering marvel that is the corrugated box. Behind its simple appearance lies generations of innovation, sophisticated manufacturing processes, and an unwavering commitment to quality and sustainability. In our interconnected world, corrugated box factories don’t just make containers – they enable global commerce, protect valuable goods, and do so while caring for our planet. That’s something worth unpacking.

Leave a Message