In the dazzling world of beauty and cosmetics, first impressions are everything. Before a customer even touches your luxurious serum or experiences your velvety eyeshadow, they encounter something equally crucial: your cosmetic packaging box. This silent salesman sits on retail shelves and arrives at doorsteps, speaking volumes about your brand’s values, quality, and attention to detail. The production of cosmetic packaging boxes is no longer just about containment; it’s a sophisticated dance of artistry, engineering, and marketing strategy that can make or break a product’s success in an intensely competitive market.

The journey of creating the perfect cosmetic box begins long before cardboard is cut or ink is printed. It starts with strategic design thinking. Modern brands understand that packaging must tell a story – whether it’s one of minimalist elegance, eco-conscious responsibility, or unapologetic luxury. Designers work closely with brand managers to translate abstract brand identities into tangible structural designs. They consider everything from the box’s opening mechanism to how it will feel in a customer’s hands. Will it have magnetic closure for a satisfying snap? Will it feature intricate die-cut windows to showcase the product? Every decision contributes to the unboxing experience, which has become a critical moment of brand connection in the age of social media sharing.

Material selection represents another pivotal phase in cosmetic packaging production. The industry has witnessed a dramatic shift toward sustainability, with brands increasingly opting for recycled paperboard, biodegradable inks, and FSC-certified materials. Luxury brands might choose rigid boxes with thick paper stock and multiple laminations for a substantial feel, while eco-brands might embrace uncoated recycled board with minimalist printing to emphasize their environmental commitment. Special coatings like soft-touch matte or high-gloss UV add sensory appeal, while foil stamping and embossing create visual drama that catches the light – and the customer’s eye.

Technology has revolutionized cosmetic box production in remarkable ways. Advanced printing techniques like digital printing allow for cost-effective short runs and incredible personalization options, while offset printing delivers unmatched color consistency for large quantities. Augmented reality features can now be integrated into packaging, allowing customers to point their smartphones at boxes to see tutorials or brand stories come to life. Sophisticated CAD software enables designers to create complex structural designs and generate precise prototypes before committing to expensive production tooling, minimizing waste and ensuring perfect execution.

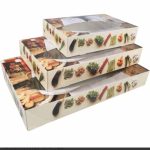

The functional aspects of cosmetic packaging boxes deserve equal attention. Beyond aesthetics, these boxes must protect delicate products during shipping and storage. Engineering considerations include crush resistance to prevent damage during logistics, and for certain products, light-blocking properties to preserve formula integrity. Smart structural designs can incorporate internal platforms, inserts, and partitions to securely hold multiple products in a single package. These practical elements work behind the scenes to ensure the product arrives in perfect condition, maintaining both the cosmetic’s quality and the brand’s reputation.

In today’s market, regulatory compliance and sustainability certifications have become non-negotiable aspects of cosmetic packaging production. Boxes must meet specific labeling requirements while environmentally-conscious consumers increasingly demand transparency about materials and manufacturing processes. Many brands now pursue certifications like Cradle to Cradle or include specific recycling instructions on their packaging. The most forward-thinking companies are implementing circular economy principles, designing boxes that can be repurposed or easily disassembled for recycling, turning packaging from a potential liability into an environmental statement.

Ultimately, the production of cosmetic packaging boxes represents a powerful convergence of form and function. It’s where marketing meets materials science, where brand storytelling becomes tactile reality. In an industry where perception significantly influences value, the box surrounding a cosmetic product does much more than simply contain it – it elevates, protects, and communicates. As consumers become more discerning and sustainability concerns grow more pressing, the innovation in cosmetic packaging production will continue to accelerate, ensuring that this crucial brand touchpoint keeps evolving to meet the beautiful demands of the future.

Leave a Message